We pride ourselves on transforming raw materials into high-precision components that meet the exact specifications of diverse industries. While our processes might seem distinct, they are all expertly grouped under the umbrella of Specialty Converting Services. But what exactly does that mean, and how do QDP Inc.’s capabilities fit into this crucial industrial category?

We pride ourselves on transforming raw materials into high-precision components that meet the exact specifications of diverse industries. While our processes might seem distinct, they are all expertly grouped under the umbrella of Specialty Converting Services. But what exactly does that mean, and how do QDP Inc.’s capabilities fit into this crucial industrial category?

Simply put, converting is the process of modifying or transforming a material from one form into another, often adding value, enhancing functionality, or creating a new product entirely. When we add “Specialty” to converting, we emphasize the high degree of precision, customization, and technical expertise required for these complex transformations. It’s more than just changing shape; it’s about engineering materials for peak performance.

QDP Inc. excels in several core Specialty Converting Services:

Laminating:

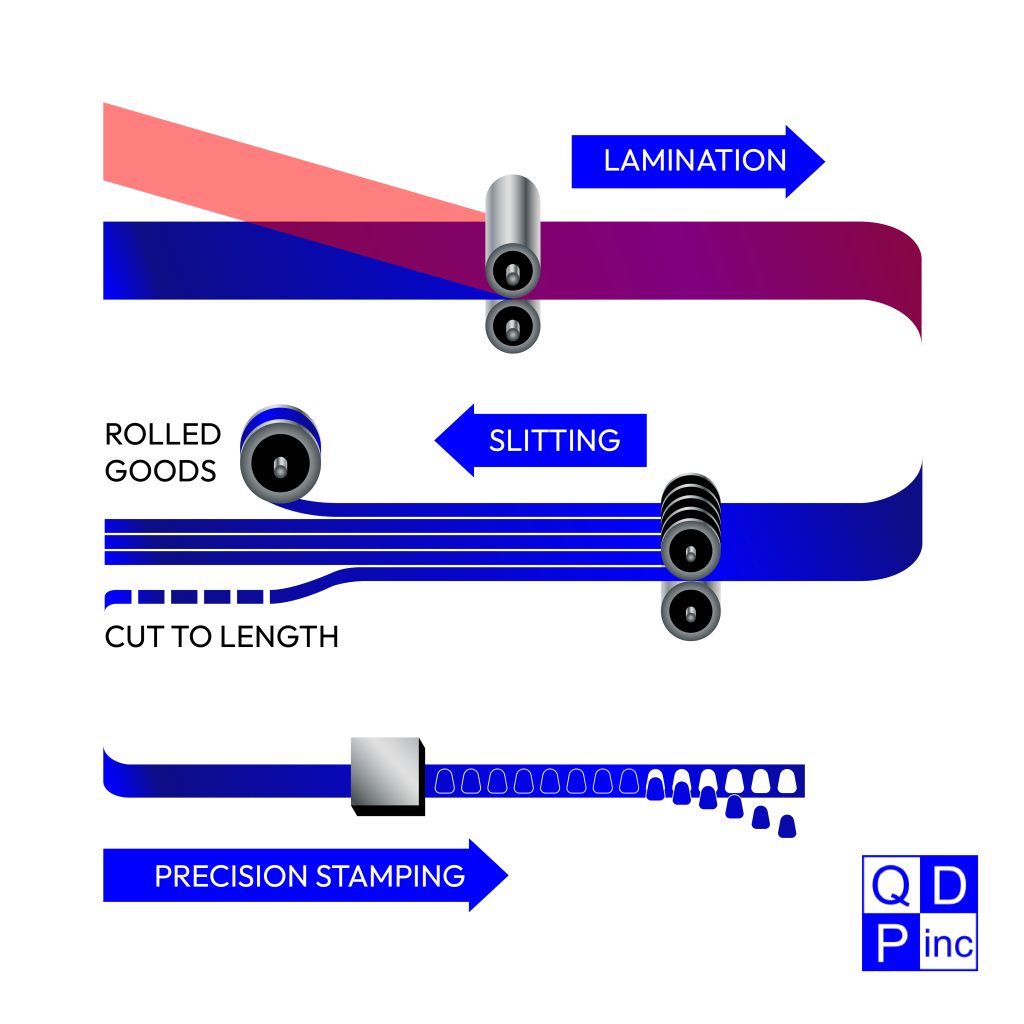

The majority of the laminating processes involves laminating a plastic film or metal foil with an adhesive and a release liner. The adhesive being used would depend on the requirements of the film or parts stamped from the adhesive laminated film or foil.

Additionally, the lamination process can be used for bonding two or more layers of material together to create a new composite material with improved properties. Whether it’s combining metal-to-plastic, plastic-to-plastic, or other substrates, our precision lamination processes ensure strong, uniform bonds. This allows for the creation of materials that are stronger, more flexible, insulative, or conductive than their individual components, meeting the stringent demands of electronics, medical, and automotive applications. The result is a unified material engineered for specific performance characteristics.

Slitting: Precision Width for Optimal Use

Our metal and film slitting services precisely cut wide rolls of material into narrower, specific widths. This process is essential for industries where material must be perfectly sized for subsequent manufacturing steps or for end-use applications. Our advanced slitting capabilities ensure exceptionally tight tolerances, consistent edge quality, and efficient material utilization. This precision is critical for seamless integration into automated assembly lines and for producing components where even minor deviations are unacceptable.

Precision Stamping: Intricate Shapes with Unrivaled Accuracy

Precision stamping is where raw films, metals, or laminations are rapidly stamped into highly intricate parts using custom tooling and powerful presses. This technique is fundamental for mass-producing complex components with unparalleled accuracy and repeatability. At QDP Inc., our stamping expertise covers a vast array of metals and plastics, delivering parts that are ready for immediate integration into electronic devices, medical instruments, aerospace systems, and more. Our commitment to “precision” ensures every stamped part meets the most demanding specifications.

Precision Cut-to-Length Services: Exacting Dimensions for Delicate Materials

Beyond slitting a continuous roll into narrower widths, our precision cut-to-length services specialize in transforming thin metals and delicate materials into precisely sized sheets or blanks. This critical process involves cutting material to exact, predetermined lengths with exceptional accuracy and consistency. Using a proprietary, custom-engineered system that includes a precision Bruderer punch press, an in-house built servo feed, and specialized roller guides, we ensure clean, square cuts. This capability is vital for applications like electrical laminations and shielding, ensuring each part is perfect for high-performance needs in both low- and high-volume production runs.

Your Partner in Specialty Converting

Each of these services—Lamination, Slitting, and Precision Stamping—is a testament to QDP Inc.’s dedication to Specialty Converting. We don’t just process materials; we apply deep engineering knowledge, cutting-edge technology, and stringent quality control to convert them into the exact components our clients need. Our ability to execute these intricate transformations with such high accuracy and efficiency makes us an invaluable partner for companies requiring precision manufacturing from concept to completion.

If your project demands the highest standards in material transformation, trust QDP Inc.’s expertise in Specialty Converting Services.

Contact Us Today to Discuss Your Next Converting Services Project