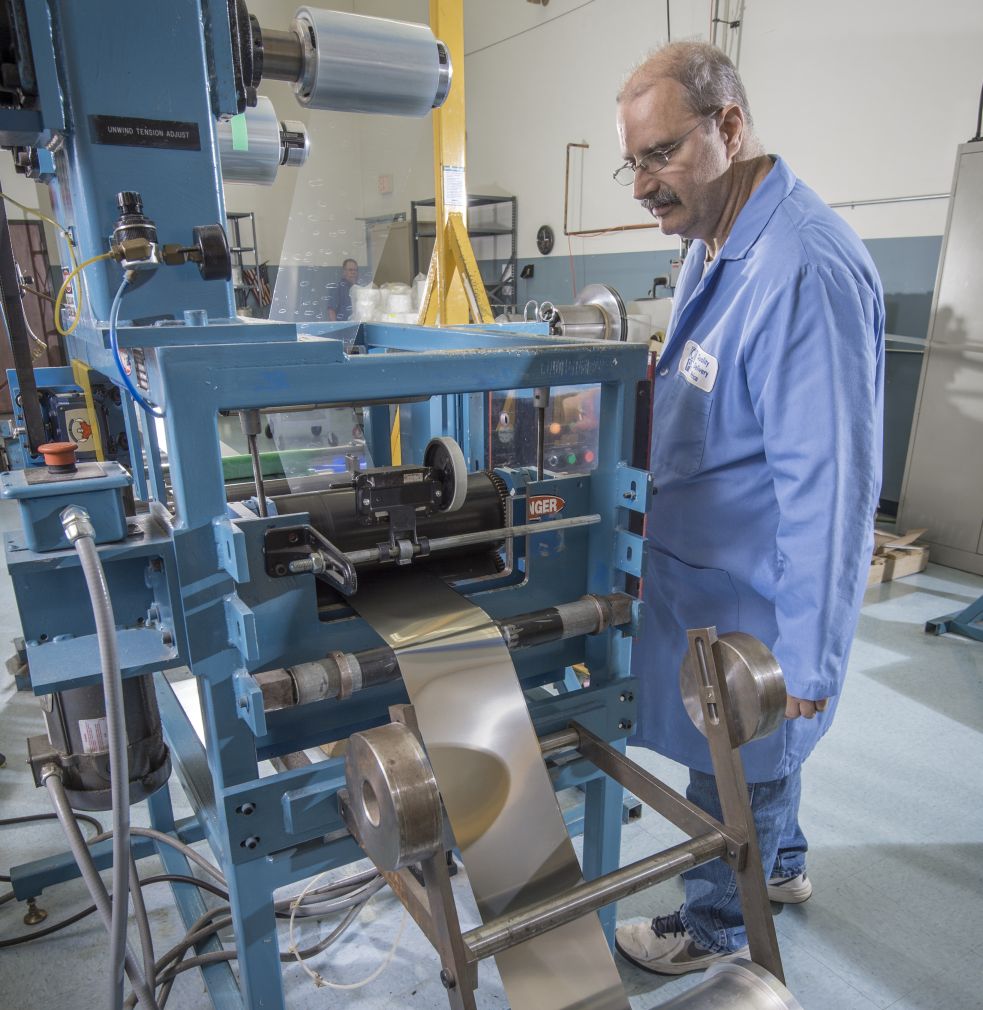

We can laminate adhesive to most metals. Metals can be laminated with a wide variety of transfer adhesives depending on the properties required. QDP can help you in determining what adhesive will work best for your application including heat activated adhesives. To ensure that the adhesive lamination is meeting the required specifications we have an in-house I-Mass SP-2000 Peel Adhesion Tester – For testing Peel Adhesion of all laminated products. Laminated metals can be supplied in up to 13” wide rolls or QDP can slit the material to the required width for you. As part of the laminating process a release liner is applied to the adhesive side of the material. If your design requires parts to be stamped from the laminated metal material, QDP has the expertise to stamp your parts for you. Some other applications that have been produced from adhesive laminated metal are heat sinks made from laminated aluminum and low voltage electrical jumpers made from copper foil with electrically conductive adhesive and stainless steel vibration dampers for the HDD industry.

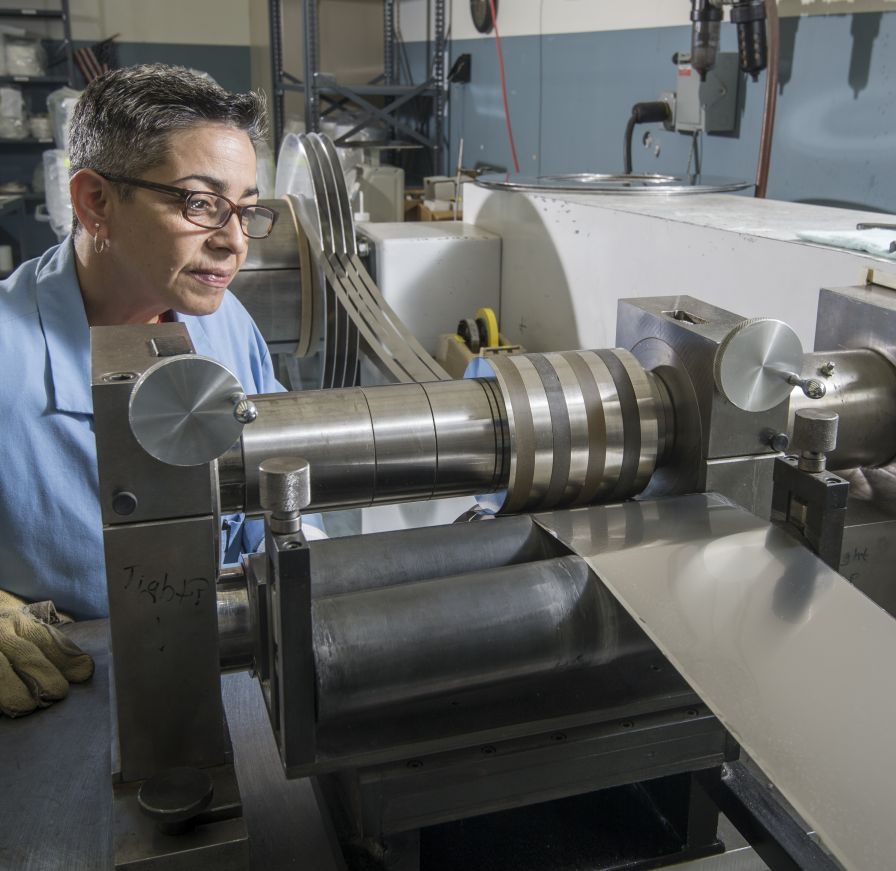

QDP’s precision metal slitting machine is used with raw and laminated metals up to 12″ wide. Thickness capabilities range up to .015″ for SST and .040″ for softer metals. We stock several blade sizes from .450″ to 2.00″. Our clients choose us as we will fabricate custom blades to suit their project and exact requirements. Our capabilities include precision metal slitting to +/- .001″ width tolerance which is considerably closer than the industry standard of +/- .010”. We have successfully slit adhesive laminated .0007” thick Stainless Steel. The experience and technology that we have gained in producing materials used as vibration dampers for the Hard Disc Drive industry has given us a leg up on other metal slitters when it comes to holding tight tolerances.